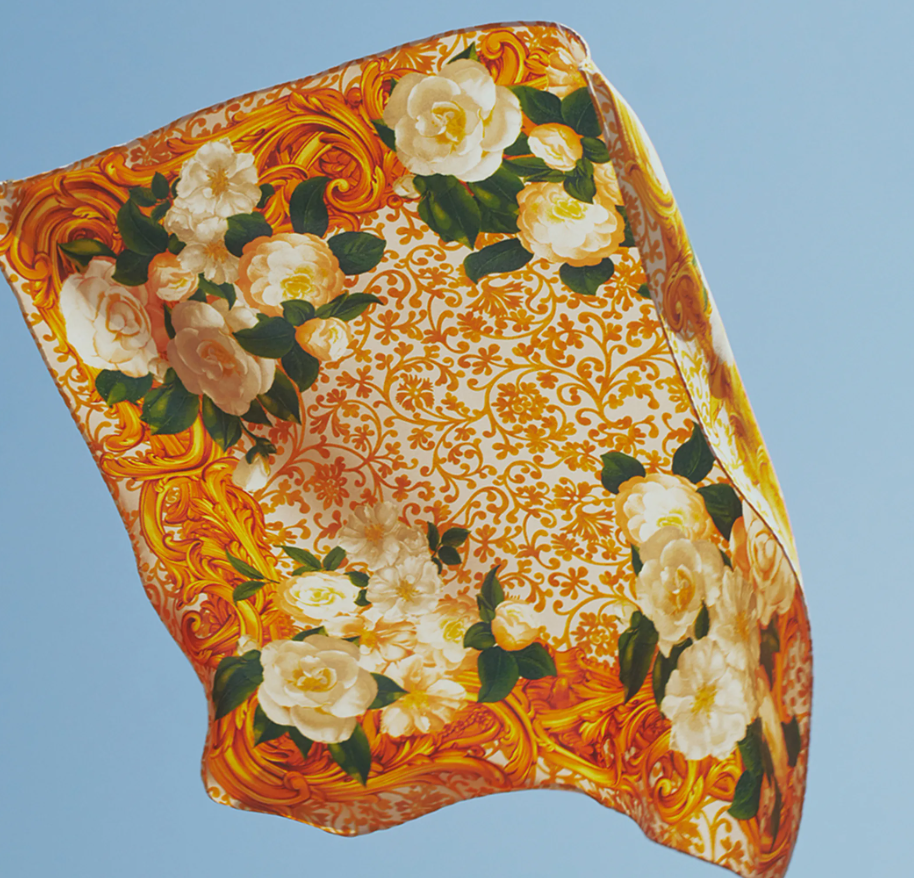

At the end of April this year, French luxury brand Chanel brought silk scarves back into the spotlight during its 2025/26 Cruise Collection show held at Lake Como, Italy. Just ahead of the show, Chanel announced an investment in its long-time silk supplier Mantero, acquiring a 35% stake in the company. Mantero, a historic family-owned business based in the Lake Como region, has been working with Chanel for over 50 years.

However, the raw silk used in Chanel’s scarves doesn’t come from Lake Como—or anywhere else in Italy. According to Mantero’s official website, all of the silk threads currently used by the company are sourced from Sichuan, Yunnan, and Chongqing in the Chinese Mainland.

Lake Como has long been the heart of Italy’s silk industry and is known as the “Silk District” (il distretto della seta). In a 2018 interview, Stefano Vitali, then Director of the Italian Silk Office, noted that the region accounted for approximately 80% of all silk production in Europe.

Why, then, is raw silk no longer produced locally in Como?

Thanks to its mild climate and abundant waterways, Lake Como began cultivating mulberry trees and raising silkworms as early as the 16th century. From the 16th to the 18th century, sericulture in the region experienced rapid growth. At its peak in the 18th century, 93% of the local population was involved in silkworm farming. Contemporary foreign travelers described homes filled with mulberry leaves and silkworms—even tables, benches, and bedsides were packed with them. In many families, every member was involved in raising silkworms.

By the 1870s, driven by Como’s success, Italy’s raw silk output far surpassed that of other European countries, second only to China globally. In the late 19th and early 20th centuries, the spread of mechanical looms during the Industrial Revolution dramatically boosted silk production and market reach. In 1904, Como boasted nearly 8,000 looms, accounting for 82% of Italy’s total. Around this time, a number of silk manufacturing firms, including Mantero, Seteria Bianchi, Frey, Ratti, and Clerici Tessuto, began to emerge.

Founded in 1902, Mantero is one of the oldest family-run silk mills in the Lake Como region and today stands as one of Italy’s largest silk producers and textile printers. Now led by the fourth-generation siblings Franco and Lucia Mantero, the company operates two factories in the area.

Mantero began supplying silk to top fashion houses in Italy and France in the 1940s and has worked with Chanel since 1973. In 2025, the company is expected to achieve double-digit revenue growth, reaching approximately 100 million euros.

Above: Siblings Franco and Lucia Mantero

So why does Mantero now source raw silk from the Chinese Mainland? The turning point came in the early 20th century, when an outbreak of microsporidiosis devastated the local silkworm industry. By the 1950s, silk farming had completely vanished from the Lake Como area.

By the late 20th century, companies like Mantero and Ratti began importing raw silk from Asian countries, including China, Japan, and South Korea, for finishing and processing. Each company developed its own unique jacquard and printing techniques, which helped them stand out. Today, nearly all silk manufacturers in the Lake Como region rely on imported silk threads from Asia—especially from the Chinese Mainland.

Laura Sofia Clerici, President of the Italian Silk Association and third-generation head of TESEO Group, a leading high-end fabric manufacturer in the Como region, remarked, “When you’re in China and see the vast expanse of silkworm farms, you immediately understand why such operations are unimaginable in Italy. The limited space and high labor costs make it impossible. Sericulture is difficult to industrialize and requires a great deal of manual labor.”

According to Il Sole 24 Ore, 95% of Italy’s silk threads in 2024 are sourced from the Chinese Mainland. As domestic production has declined or shifted, the cost of high-end fabrics continues to rise. The Italian Fashion Industry Federation (Confindustria Moda) has submitted a detailed plan to the Ministry of Enterprises and Made in Italy (MIMIT) to restart domestic silk raw material production—a strategy expected to yield initial results within four years.

Sergio Tamborini, President of Confindustria Moda, noted, “Rebuilding the supply chain from scratch is, of course, incredibly difficult. We have to start with mulberry trees, ensure a sufficient supply of leaves to feed the silkworms, and manage the cocoons properly. It’s a complex production process. Although some mechanization is now possible, unlike in the past, it still requires significant investment and a long lead time to get started.”

In recent years, the Lombardy region and the local government in Como have been working to attract younger generations to sericulture through initiatives in education and entrepreneurship.

For example, Lombardy has launched a Young Farmers Settlement Grant, offering first-time farmers aged 18 to 40 non-repayable subsidies of €40,000–€50,000 and low-interest loans, with priority given to sericulture projects. The Como Chamber of Commerce has also established the ComoNEXT incubator to provide young sericulture entrepreneurs with laboratory facilities, mentors, and access to market resources.

| Sources: Chanel Magazine, Como Silk Museum, Forbes Italy, FashionNetwork.it, Il Sole 24 Ore, Mantero official website

| Image Credit: Chanel official, Como Silk Museum official Instagram, Mantero official website, Serinnovation.it

| Editor: Esther

About the Luxe.CO Silk Culture Division

In March 2025, Luxeplace officially launched its Silk Culture Division, with a mission to promote Chinese silk culture and enable more high-level industry readers to fully appreciate its richness and immense potential. The initiative aims to foster dialogue and drive the renewal and modernization of China’s silk industry.

In addition to producing original, high-quality content, Luxeplace will organize a range of thoughtfully curated cultural and industry events—including traceability journeys, forums and workshops, cultural and art exhibitions, and more. Guided by first principles, these activities will trace silk to its source—from culture to commerce, from raw material to craftsmanship, from history to the present, and from China to the world—bridging the entire value chain to uncover and reinterpret the essence of silk culture and craftsmanship from a fresh perspective.

Contact the Luxe.CO Silk Culture Division: silk@luxe.co