Past Highlights from the Luxe.CO Silk Culture Column:

- The World’s Earliest Luxury Fabric Was Actually “Made in Chengdu”!

- Masters of Shu Embroidery, Hangluo, and Xiangyun Silk Selected as Sixth-Generation National

- Intangible Cultural Heritage Inheritors

- Where Did the Silk for Hermès’ First Scarf Come From?

In last week’s newly released article from the Luxe.CO Silk Culture Column, we traced the origins of the first silk scarf created by French luxury giant Hermès in 1937.

During our research, we delved deeper to uncover more behind-the-scenes details about Hermès’ silk products. It became increasingly clear that behind every globally renowned Hermès silk scarf is a meticulously managed, top-tier supply chain—one that has been refined for nearly a century. From raw materials to manufacturing techniques and production processes, every link is under Hermès’ strict control. This supply chain mainly involves the following stages and companies:

- Raw Silk Supply: Bratac, Brazil

- Fabric Weaving: Tissages Perrin, Le Grand-Lemps, France

- Scarf Manufacturing: Hermès-Owned Factories and Workshops in Lyon and Surrounding Areas

Raw Silk Supply: Bratac, Brazil’s Only Silk Reeling Manufacturer

According to Brazilian newspaper O Estado de S. Paulo, in 2009, then-Hermès CEO Patrick Thomas expressed his admiration for Brazilian silk during the launch of Hermès’ first store in São Paulo, stating without hesitation, “Brazilian silk is the best.”

A report published on Hermès’ official website, written in 2020 by the University of Cambridge and titled Hermès’ Silk Supply Chain: The Impact on Biodiversity, revealed that “Hermès has long sourced cocoons from smallholder farmers in the state of Paraná, Brazil, through local partners.”

Above: Bratac raw silk

By examining Hermès’ Universal Registration Documents from recent years, Luxe.CO identified this local partner as Bratac, currently the only remaining silk reeling factory in Brazil. According to a 2016 Forbes Brazil report, Hermès has exclusively used silk threads produced by Bratac for its scarves since 2006.

According to its official website, since 2010, Bratac has been the only manufacturer in the Western Hemisphere capable of producing natural silk threads on an industrial scale. The company operates two factories: one in Londrina, Paraná, and another in Bastos, São Paulo. Bratac is deeply involved in every stage of silk production, including varietal preservation, silkworm egg production, the “company + farmer” mulberry cultivation model, silkworm rearing, cocoon production, silk reeling, and twisting.

Bratac employs more than 1,000 staff and sericulture technicians directly and works with over 1,700 sericulture households. It produces about 300 tons of silk thread annually, primarily of 6A-grade quality.

In Brazil, sericulture is mostly carried out on small family farms. By signing contracts with local farmers, Bratac becomes involved in every phase of silkworm cultivation, closely monitoring the progress of cocoon production, maintaining tight communication with farmers, and providing comprehensive technical support to ensure the final silk threads are of optimal quality.

Bratac can truly be considered a pioneering enterprise in Brazil’s sericulture industry.

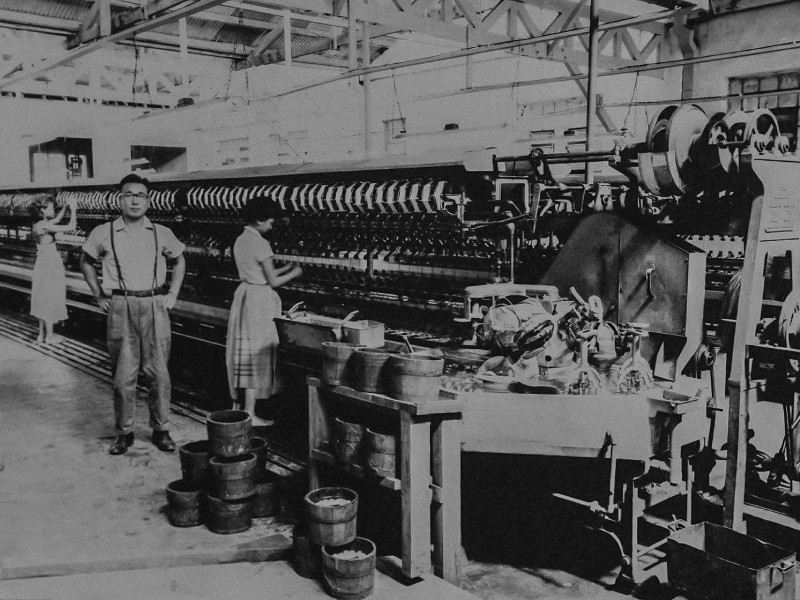

According to the China Sericulture Science journal, silkworms were introduced to Brazil in the early 19th century. However, Brazil’s sericulture industry only began to truly develop in the 1930s, driven by Japanese immigrants. Bratac was founded in 1940 in Bastos, Brazil, by Japanese immigrant Kenji Amano and has since passed into its third generation of family ownership. At its peak, Brazil had 15 domestic silk manufacturers like Bratac, but as the global cocoon and silk market declined, most companies exited the industry.

Above: In 1953, Bratac introduced Brazil’s first fully automated spinning machine

According to the website of the Brazilian Confederation of Agriculture and Livestock, Brazil is now one of the world’s major raw silk producers, with production mainly concentrated in the southern state of Paraná (83%), followed by São Paulo (12%) and Mato Grosso do Sul (5%). Thanks to favorable climate conditions, soil management, and support from technologies such as larval genetic improvement, Brazilian cocoons boast exceptional quality, with an average filament length of up to 1,200 meters. They are whiter in color, less prone to breakage, and softer to the touch.

Brazil and China—two major silk-producing powers from East and West—have maintained increasingly close exchanges in recent years. In 2024, on the 50th anniversary of the establishment of diplomatic relations between China and Brazil, Bratac sent an executive delegation to silk-producing regions in Sichuan, Hangzhou, and Guangxi, China, for field visits and exchange. China Daily described Brazil as “a key pivot point for extending the 21st-Century Maritime Silk Road to Latin America.”

Fabric Weaving: Perrin, a Fifth-Generation Family Business in France

According to Hermès’ 2019 Universal Registration Document, the weaving and processing of the brand’s silk textiles is handled by the leading French manufacturer Tissages Perrin. Tissages Perrin is part of the French textile group Perrin & Fils (Perrin Group), which specializes in weaving silk and other high-end fabrics such as twill, cashmere, and velvet.

Hermès has been a shareholder in the Perrin Group since 1989, initially holding up to 60% of the company before gradually reducing its stake. According to Hermès’ 2022 Universal Registration Document, “Hermès Textile Holding owns a 40% stake in Perrin & Fils.”

The Perrin Group was founded in 1929. Its roots, however, go back to the 19th century when founder Alexandre Perrin worked in the textile industry in the Nord-Isère region of France. His son, Eugène, influenced by his father, developed a strong interest in natural silk. Upon returning from the United States in 1929, Eugène established the Tissages Perrin factory in Le Grand-Lemps, Isère, expanding the business to include silk weaving for lingerie, swimwear, home décor, and high-end ready-to-wear and accessories.

According to a 2012 report by Le Monde, Perrin Group weaves 80% of France’s annual imported silk threads.

Currently, the Perrin Group’s operations focus on two main areas:

-

Tissages Perrin, which specializes in silk fabric weaving. The factory operates about 60 looms, spans 8,100 square meters, and employs around 100 people. It produces approximately 2 million meters of fabric annually.

-

Alpasoie, the group’s latest expansion in 2022, is located in the town of Apprieu, Isère, just 5 km from Le Grand-Lemps. Alpasoie offers bespoke services for high-end clients, producing accessories such as ribbons and headbands, from prototype development to small-batch production.

Today, the Perrin Group is managed by the fifth generation of the family. Jean-Laurent Perrin currently serves as CEO (pictured on the left below), alongside his brother, Jean-Hugues Perrin (center), and cousin, Sébastien Perrin (right).

Scarf Manufacturing: Hermès-Owned Factories and Workshops in Lyon and Surrounding Areas

Creating a Hermès silk scarf involves multiple complex steps, including design, screen preparation, silk-screen printing, dyeing, and hand-rolling the edges. All these processes take place in Hermès-owned factories and workshops in and around Lyon, widely regarded as the “Silk Capital of Europe.”

According to the official website of China’s Belt and Road Initiative, Lyon was a key node on the ancient Silk Road in the West and served as a distribution hub for Chinese silk products in Europe. In 1536, the first silk weaving workshop was established in Lyon, marking the start of the city’s thriving silk industry. By the 17th and 18th centuries, Lyon had become one of Europe’s most important silk production centers. In the 19th century, silk accounted for three-quarters of Lyon’s industrial output and became the cornerstone of the city’s economy.

In 2001, Hermès established Hermès Textile Holding to consolidate all of its textile subsidiaries, covering every stage from apparel manufacturing and weaving to pattern preparation and dyeing. The workshops involved in scarf production are primarily located in Lyon or nearby, and include:

- Ateliers AS

In the 1980s, Hermès acquired the Ateliers AS workshop in the town of Pierre-Bénite, south of Lyon. This facility specializes in flatbed printing for accessories like scarves and ties. In 2001, it was integrated into Hermès Textile Holding.

Pierre-Bénite is also the headquarters of Hermès Textile Holding and home to one of Hermès’ main textile production bases. According to Hermès’ production disclosures, all of its silk products—particularly ties and scarves—are printed in weaving facilities located in the Lyon area. In July 2023, Hermès announced an expansion of the Pierre-Bénite site to increase scarf production capacity.

- SIEGL

In 2003, Hermès Textile Holding acquired SIEGL, a textile printing facility, from the aforementioned Perrin Group. Founded in 1957 and located in Le Grand-Lemps (about an hour from Hermès’ Lyon workshops), SIEGL is responsible for printing patterns on Hermès scarves.

- Gandit

Located in Bourgoin-Jallieu, a suburb of Lyon, Gandit is a screen engraving workshop with over 70 years of history. It has been part of Hermès since 2004 and is responsible for the engraving and preparation of designs for scarf production.

From concept to finished product, creating a Hermès silk scarf takes approximately two years. Hermès has a team of over 50 artists and illustrators from around the world who are responsible for designing the patterns. After the hand-drawn designs are created, artisans use digital drawing tablets and styluses to trace each line into graphic design software meticulously—a highly time-consuming process. Each design takes an average of more than 600 hours to complete, with some complex patterns requiring several thousand hours.

The next step is analyzing the color layers and preparing the screens for silk-screen printing. Each color in a design requires its own screen. For example, a classic Hermès scarf with 48 colors necessitates 48 separate screens. Once all the screens are prepared, printing begins, one color at a time. The process starts with the outlines, followed by color filling.

After printing, the silk fabric undergoes color fixation, washing, and drying. Finally, the signature finishing touch—hand-rolled edges—is applied. Craftspeople delicately roll the edges of the scarf inward by hand and sew them with silk thread, creating precise 90-degree corners —a hallmark of Hermès craftsmanship.

About the Luxe.CO Silk Culture Division

In March 2025, Luxe.CO officially launched its Silk Culture Division, with a mission to promote Chinese silk heritage and help high-end industry professionals gain a deeper understanding of the richness and boundless potential of Chinese silk culture. The division aims to inspire dialogue and innovation in the revitalization and modernization of the silk industry.

In addition to producing original high-quality content, Luxe.CO will launch a series of curated cultural and industry initiatives, including source-tracing journeys, forums and workshops, art exhibitions, and more. Guided by first principles, the division seeks to uncover the origins of silk—from culture to commerce, from materials to craftsmanship, from history to the present, from China to the world—integrating the entire industry chain and exploring the essence of silk culture and craftsmanship from a new perspective.

Contact email for the Luxeplace Silk Culture Division: silk@luxe.co