On June 11th, Pitti Uomo launched its 106th edition at Fortezza da Basso in Florence.

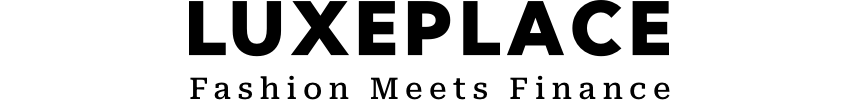

The Chinese Ningbo-based high-end cashmere yarn export company Consinee Group collaborated with the Italian fashion brand Vitelli for the second time to launch a co-branded series named The New Regeneration.

Luxeplace.com talked to Boris Xue, chairman of Consinee Group, and Mauro Simionato, Vitelli’s founder and creative director, to learn the details and reasons behind this collection.

This is Consinee and Vitelli’s second collaboration. The two launched their first co-branded series at the 105th Pitti Uomo in January. (In Pitti Uomo, Discover the Latest Menswear Trends with Luxeplace)

This time, they focused on regenerative cashmere again. “For cashmere is so precious. It’s always our desire to make used clothes regenerative,” Boris Xue told Luxeplace.com. The special installation at Pitti Uomo set by Consinee and Vitelli stressed the urgency of promoting sustainable production practices in the luxury and design sectors and solving the problem of “regeneration”by introducing a new concept of “high-quality recycling,” reusing pre-consumer material waste as the “pure” source of the new generation of luxury.

Image above: Mauro Simionato, Vitelli’s founder and creative director, before the Consinee × Vitelli co-branded series(Photo/Xiaoyue Zhao)

“This time, our collaboration mainly focuses on the regeneration of raw material.” However, the first challenge facing recycling raw material is ensuring its safety.”We started to recycle cashmere 15 years ago but failed because of the disinfection problem.”

Boris Xue told us about a failed experience of a British person many years ago: a customer suffered from skin disease after wearing clothes made of recycled cashmere. Although it was uncertain whether the cashmere caused the disease, it was nipped in the bud.

Now, Consinee has come up with a solution: “We use high-temperature steam at 800 degrees to disinfect the recycled cashmere and import a capsule disinfectant from Japan for sterilization.” Therefore, the leftovers from the production process gain new life instead of ending up in the landfill.

It differs from common production because Consinee’s exploration of optimizing remaining materials starts from the design stage, meaning the design is informed rather than defined by raw material.

“Here, these are the old materials with rich colors; they are regenerated with more different and unique colors that can’t be replicated.”Boris Xue showed Luxeplace.com. After disinfection, Consinee would categorize the materials according to their original color, spinning them into new colors without second dyeing at the clients’ request.

As for the blending technology, Mauro Simionato said, “I developed a technology of blending waste fibers, which not only optimizes the color and gradient effect of the yarn, but it can also blend up to five colors in a single blend.”

Image above: The regenerative cashmere yarn made by Consinee and Vitelli through the technology of blending waste fibers

The final result would be special and fabulous owing to the uniqueness of leftover fibers and the combination of different yarns.

With this technology, Consinee tried to explore elements of harmony and inheritance in Chinese culture from the perspective of non-native designers in the second cooperation.

“I was happy to show at Pitti for fashion and luxury in Florence a Chinese story with the Chinese aesthetic, but through the filter of my design, and I’m Italian.” Mauro Simionato said.

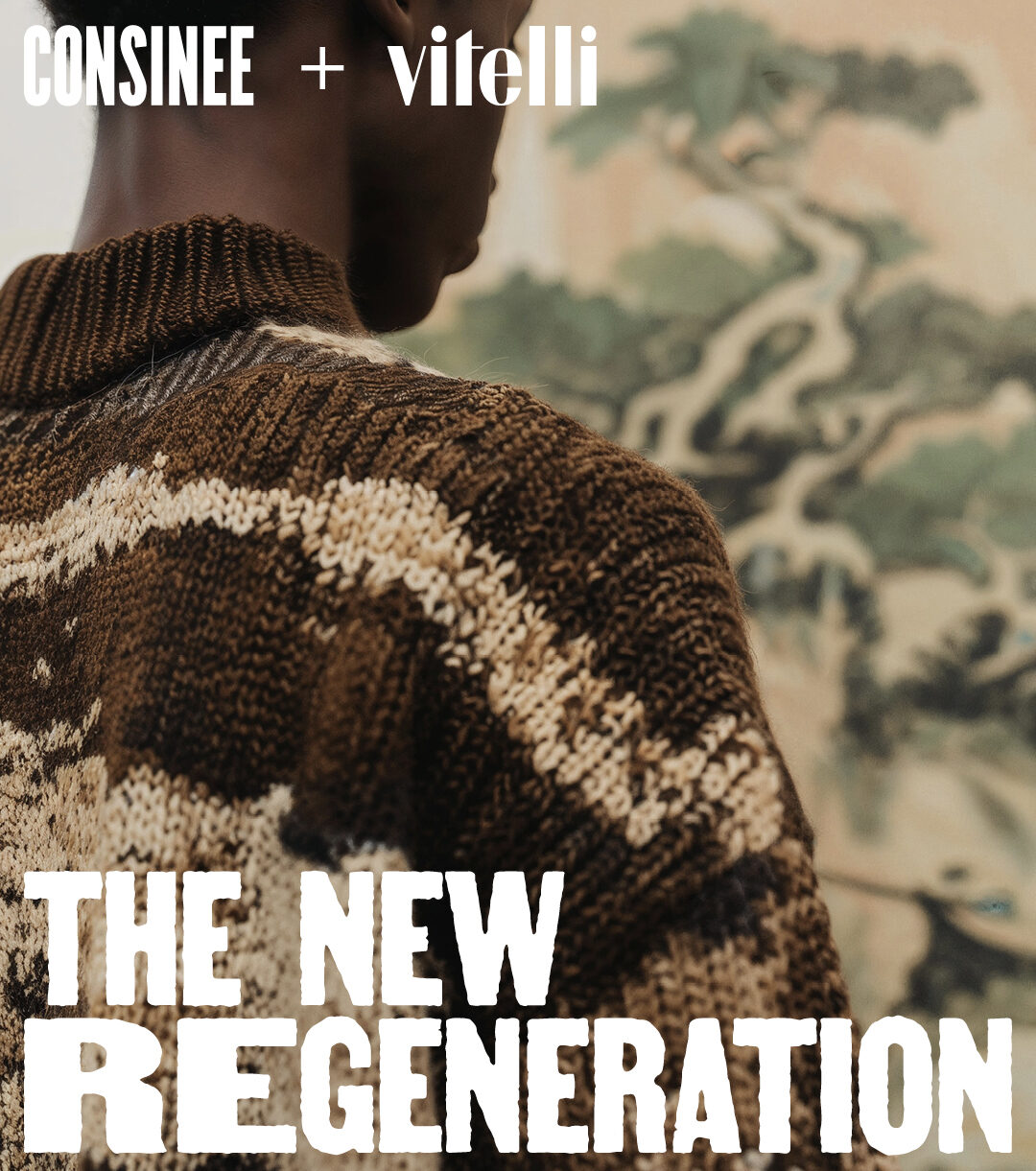

“I did some research before and after, and I saw the paintings and there was a lot of development, but a certain purity was lost in a way.” Before starting the design, Mauro Simionato went to Ningbo, Consinee’s main production base. ” “I went to the Ningbo history museum. I spent a lot of time there, so all these like the landscape painting, the clothes, and I want to tell a bit of this story to the western people and also the clients of my brand.” He draws inspiration from the local Wa Pan Wall, Chinese traditional Shan Shui paintings, Hanfu, Celadon ceramics, and Bian embroidery, creating colorful and special knitwear capsule collection using Consinee’s regenerative yarns.

Image above: Inspired by Wa Pan Wall of the exterior wall of Ningbo Museum. Wa Pan is a traditional craftsmanship technique with a long history in the eastern Zhejiang region. Craftsmen build walls and repair damaged houses, bricks, tiles, stones, and even fragments of different sizes and materials together.

Image above: The exterior wall of Ningbo Museum

Image above: SHAN SHUI BROWN blended by celadon brown and celadon beige yarns with the inspiration from shan shui painting.

Boris Xue told Luxeplace.com that the proportion of recycled cashmere in the total yarn production of the group is still very small. “We produce more than 7000 tons of cashmere yarn per year, of which recycled cashmere can reach about 100 tons. In the beginning, we don’t want to expand widely. We mainly cooperate with major brands such as H&M and COS. Last year, we sold about 70 tons to them, and this year the number will increase. Their unsold old clothes will also sent to us for recycling.”

Some of the recycled cashmere comes from suppliers that specialize in recycling waste clothes and exchanging old clothes for yarn. “Making a new piece of clothing requires 300 grams of yarn, and you can exchange 4-5 pieces of clothing for the raw materials of a new one,” he said.

Consinee is also actively exploring the scale and standardization of cashmere recycling, “Currently, we are the only company that has obtained full industry chain certification in China. We developed the national standards for cashmere recycling as well as the craftsmanship.”

Mauro Simionato also stated, “Pre-consumer recycling can not only ‘do well’ but can also be scaled up, but it requires time to carefully design. This is the long-term goal jointly pursued with Consinee, which we now refer to as ‘the next generation regeneration. ‘”

| Image Credit: on-site photography by Luxeplace.com, Consinee, Ningbo Museum Official WeChat account

| Reporter:Huang Yuting

| Editor: